|

| |

|

| |

|

| |

|

| |

*Additional Information

1)Reliability

Low vibration and low noise have been achieved by high-rididity,

new type CNC device H.MARK-30D and new servo system.

2)New Z-Axis structure

High-speed and low vibration have bben achieved by Direct drive

Z-Axis Linear Motor

3)High productivity with high speed spindle

High speed spindle with air bearing have been

developed based on Hitachi's experience and

know-how.

4)Standard equip function for high accuracy and high productivity.

Quick insert changer(QIC) as standard spec.

|

|

| |

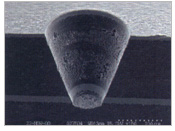

Cross secton of drilled hole(¨Ş50§) |

|

|

| |

| 5)High-precision drilling example |

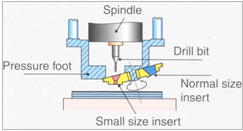

6)High accuracy blind hole function |

|

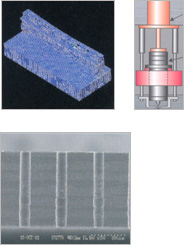

7)Quick Insert Changer(QIC) |

|

|

|

|

Spindle speed : 330K Spindle speed : 330K

Hole Diameter : ¨Ş0.080mm Hole Diameter : ¨Ş0.080mm

Material : t0.1mm x 4high Material : t0.1mm x 4high |

Accuracy of hole depth : ˇľ15§ |

|

|

| |

| 8)CNC H.MARK-50D |

|

| |

| *Machine specifications |

|

| Item

|

Unit |

ND-6Qs210E |

ND-6Qs180E |

ND-6Mb210E |

ND-6Mb180E |

| Number of stations

|

- |

6 |

ˇç |

ˇç |

ˇç |

| Spindle spacing

|

mm |

538 |

465 |

538 |

465 |

| Drilling area

|

mm |

538ĄŞ690 |

465ĄŞ690 |

538ĄŞ690 |

465ĄŞ690 |

| ADC Number

|

Tool/Axis |

1050 |

650 *1 |

300 |

200 |

| X,Y Axis positioning speed

|

m/min |

60 |

ˇç |

ˇç |

ˇç |

| Z Axis feed rate

|

m/min |

0.101~12.7 |

ˇç |

ˇç |

ˇç |

| Z Axis retraction rate

|

m/min |

50 |

ˇç |

ˇç |

ˇç |

| Positioning accuracy

|

mm |

ˇľ0.004(Hitachi measurement standard) |

ˇç |

| Spindle speed

|

min-©ö |

30,000~330,000 |

20,000~160,000(Option:200k, 300k) |

| Drilling accuracy

|

mm |

ˇľ0.015(Hitachi measurement standared) |

ˇç |

| Drill size range

|

mm |

Max¨Ş3.2(Shank ¨Ş2.0) *2 |

Max¨Ş6.35(Shank ¨Ş3.175) |

| CNC

|

- |

Hˇ¤MARK-50D |

ˇç |

ˇç |

ˇç |

| Power requirement

|

- |

3Phase 200V ˇľ20V 50/60Hz

|

3Phase 200V ˇľ20V 50/60Hz

|

| KVA |

15 |

ˇç |

15 |

ˇç |

| Air Requirement

|

KPA |

740~760 |

ˇç |

640~690 |

ˇç |

| §¤/min |

900 |

ˇç |

900 |

ˇç |

|

*1 ¨Ş0.1mm~1.6mm dia. Drill : Tool magazine for ringless tool (200pcs drill bit)

¨Ş1.6mm~4.0mm dia.drill : Tool magazine

for too with ring (50pcs drill bit)

*2 When the drill bit of diameter beyond ¨Ş1.6mm is used, a hole is over by using step drilling, and you must do drilling.

|

| |

|

| Standard Specifications |

Optionals |

Pin clamp system

Quick Insert Changer(QIC)

¨Ş 0.1mm Tool height detector(Patented)

¨Ş 0.1mm BDD(Broken Drill bit Detector)

Automatic drill stroke adjustment |

Drill bit diameter check(Type1 or 2)

200,000min-©ö spindle(Shank ¨Ş3.175mm)Only Mb series

High-precision blind hole function(new)

Vacuum shutter

Stand-alone vacuum system

Insert abrasion detector/compensation(new)

270,000 min-©ö spindle (Shank ¨Ş3.175mm) Only Mb Series

|

|

| |

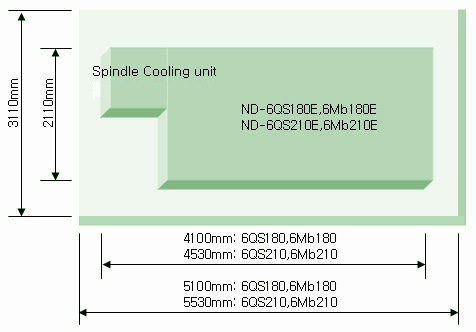

| *Floor plan |

|

| |