|

| |

|

| |

|

| |

|

| |

| *Additional Information

|

1)Dramatic progress of drilling accuracy

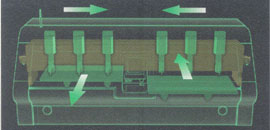

Momentary stop control with

Symmetrical X,Y axis movement will be achieved

2)Optimum design for machine structure

Optimum design and low vibration for Symmetrical

movement are realized by various simulation |

|

3)Drilling accuracy 8um will be realized

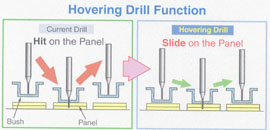

4)Hover Drill Function

Aims to improve productivity 15~20% by

optimizing(shortening) Z-axis stroke in

samll-diameter drilling |

|

|

| |

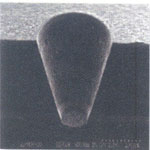

5)High-precision drilling example

-Spindle speed:330k

-Hole Diameter:0.08mm

-Material:t0.1mmx4high

|

6)High accuracy blind hole function

Accuracy of hole depth : ˇľ15um

|

|

| |

7)CNC H.MARK-50D

Process status page

|

Tool Data

|

Program control

|

|

| |

| *Machine specifications |

|

| Item |

Unit |

ND-6T210E |

| Number of stations |

- |

6 |

- |

- |

- |

| Spindle spacing |

mm |

538 |

- |

- |

- |

| Drilling area |

mm |

533 x 690 |

- |

- |

- |

| ADC Number |

Tool/Axis |

1050

*1 |

300

*4 |

300 |

300

*4 |

| X,Y Axis positioning speed |

m/min |

60 |

- |

- |

- |

| Z Axis feed rate |

m/min |

0.101~12.7 |

- |

- |

- |

| Z Axis retraction rate |

m/min |

50 |

- |

- |

- |

| Positioning accuracy |

mm |

ˇľ0.004 |

- |

- |

- |

| Spindle model |

- |

UH33AL |

H927AL |

H920BL |

H916CL |

| Spindle speed |

min-©ö |

30,000~330,000

*2 |

20,000~270,000 |

20,000~200,000 |

20,000~160,000 |

| Drilling accuracy |

mm |

ˇľ0.008

*2 |

- |

- |

- |

| Drill size range |

mm(Max) |

¨Ş4.0(¨Ş2.0shank)*3 |

¨Ş4.0(¨Ş3.175shank) |

¨Ş6.35(¨Ş3.175shank) |

¨Ş6.35(¨Ş3.175shank) |

| CNC Equipment |

- |

Hˇ¤MARK-50D(Windows XP) |

| Power requirement |

- |

3Phase200Vˇľ20V 50/60Hz |

| KVA |

18 |

- |

- |

- |

| Air Requirement |

KPA |

590~690 |

700~740 |

590~690 |

700~740 |

| §¤/min |

900 |

- |

- |

- |

| QIC |

type |

3 position |

3 position |

2or3 position |

2or3 position |

|

| |

*1 ¨Ş0.1mm~1.6mm dia. Drill : Tool magazine for ringless tool (200pcs drill bit)

*2 Hitachi measurement standard

*3 When the drill bit of diameter beyond ¨Ş1.6mm is used, a hole is over by using

step drilling

*4 Use drill bit with sinning over¨Ş3.0mm

|

| |

| *Standard Specifications |

*Optionals |

Pin clamp system

Hovering drill function

¨Ş 0.1mm BDD(Broken Drill bit Detector)

Automatic drill stroke adjustment

Quick Insert Changer(QIC, 2or3 position)

Drill bit diameter check(Drill analyzer) |

H920BL, H927AL, UH33AL Spindle

Drill bit diameter check(Type2)

Tool height compensation

¨Ş0.075mm BDD(Broken Drill bit Detector)

Air dryer filter unit

Stand-alone vacuum system |

|

| |

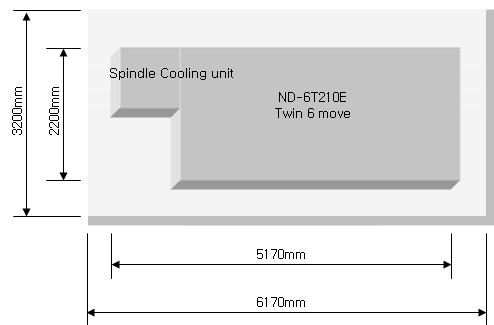

| *Floor plan |

|

| |

| |

| |